Maize Dry Milling Process. Dry Milling MAIZE Dry Milling. Arepa flour is made in a dry milling process which removes the pericarp and the germ from maize. The Corn Dry-Milling Process The corn dry milling process is a less versatile less capital intensive process that focuses primarily on the production of grain ethanol. After mill you will get maize grits maize meal maize starch and maize germ which are necessary in making food and ethonal.

There are two main way of maize milling. Wet milling and dry milling which is mainly used in industry alcohol process. The normal flow is through break rolls and then to sifters. Therefore arepa flour may be expected to differ from whole maize flour and this was in fact reported by Cuevas et al. The maize dry milling process fractionates the maize kernel into the germ pericarp and endosperm components. The break rolls are followed by reduction roll which grind the endosperm to the desired particle size.

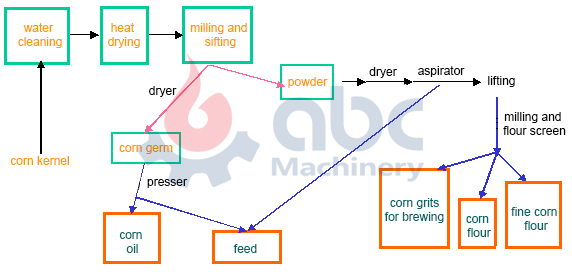

In the process of corn processing the key of maize flour quality depends on embryo remove it is also the important indicators of corn dry milling technology.

Wet milling and dry milling which is mainly used in industry alcohol process. And according to the height of water adjust corn germ extraction can be divided into dry method and wet method and half wet method. Arepa flour is made in a dry milling process which removes the pericarp and the germ from maize. The Corn Dry-Milling Process The corn dry milling process is a less versatile less capital intensive process that focuses primarily on the production of grain ethanol. Dry milling is often used to describe three different processes when talking of maize. Maize milling plant or corn flour milling plant adopts dry method and excellent automation solution and furthest reduces manual cost and production costThe professional corn processing project designers and commissioning engineers team ensures the technological advancement which not only reduces energy consumption but also reduces the impurities dust and bran speck impact to end products.