Electropolishing Stainless Steel Process. Electropolishing is also referred to as electrochemical polishing anodic. Electropolishing The actual electropolishing is performed in this phase to smooth brighten and deburr the metal. The two processes have some similarities but. Tance of stainless steel makes it the material of choice for process equipment and many consumer products.

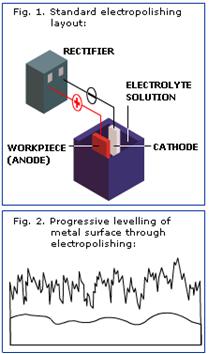

Electropolishing The actual electropolishing is performed in this phase to smooth brighten and deburr the metal. For stainless steel materials electropolishing and passivation are two of the most popular finishing methods. I am manufacturing SS flexible hose made of SS291 and 304 And i need to know the process of doing electropolishing to get mirror finish. This gives anode current densities around 20 to 40 ampsdm 2 amps per square decimetre. Typical applications are found in the pharmaceu-tical biochemical and food-processing industries. Essentially it is the opposite of electroplating rather than depositing a metallic layer metal is removed from the surface on a microscopic level.

Chime right in topic 53891 Electropolishing stainless steel tubes.

The stainless being electropolished becomes sacrificial while the electric current removes and smooths its surface. The electropolishing process for stainless steels. Passivation is a chemical process that has been used for years to help restore contaminated stainless steel to original corrosion specifications. Advertise Here Help Wanted Current QAs Search the Site. The two processes have some similarities but. Electropolishing is quickly becoming a replacement process for a long established treatment.